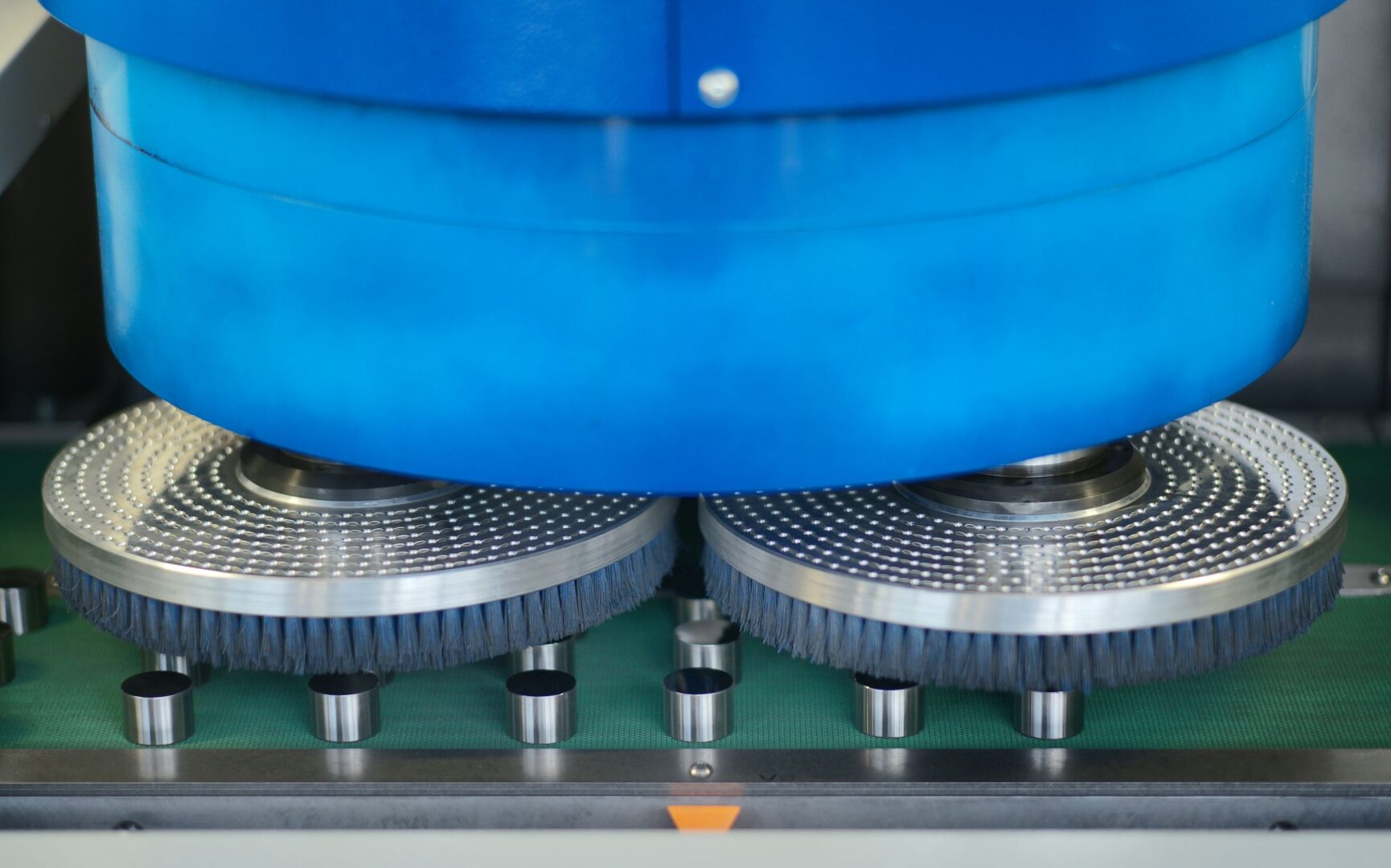

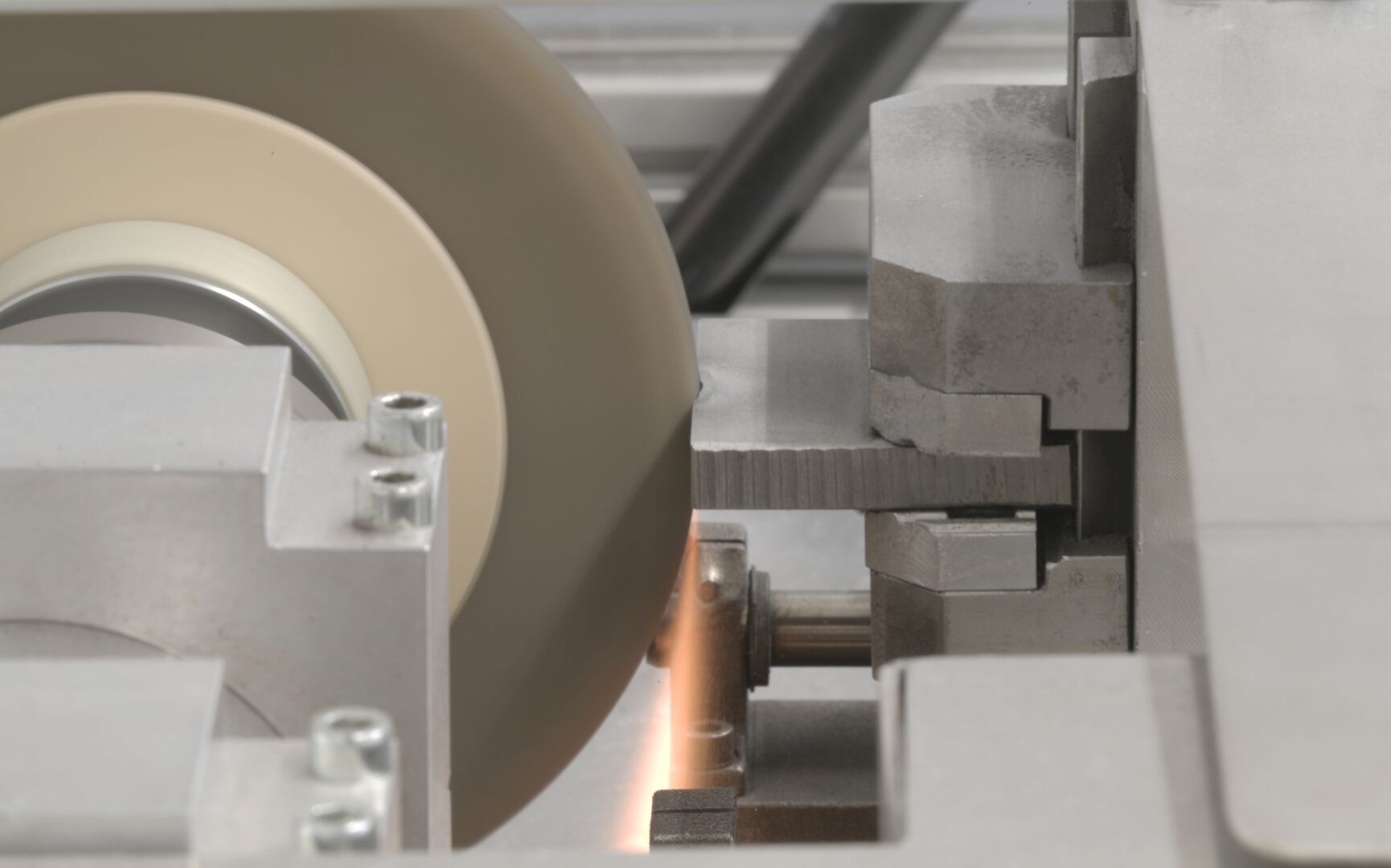

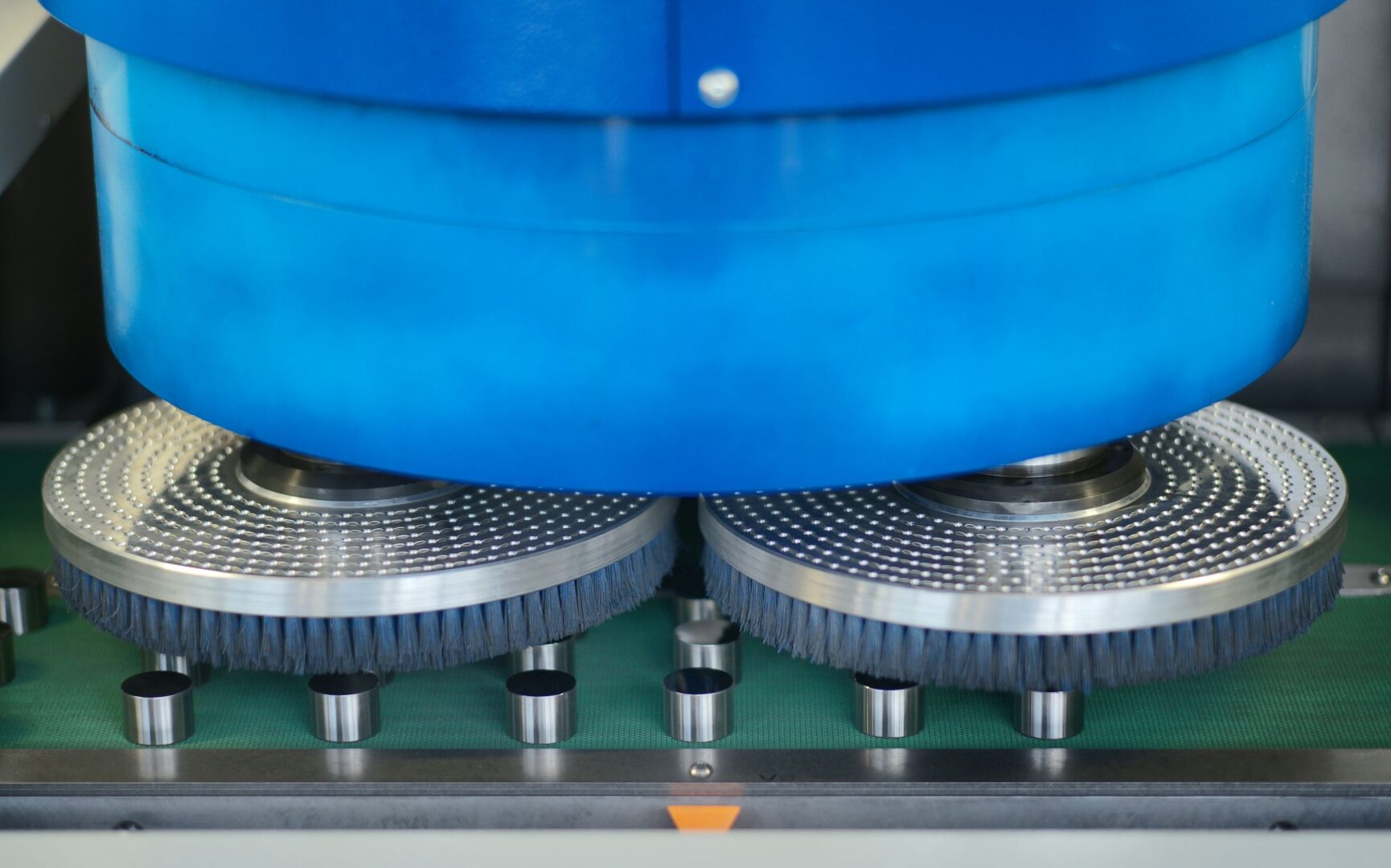

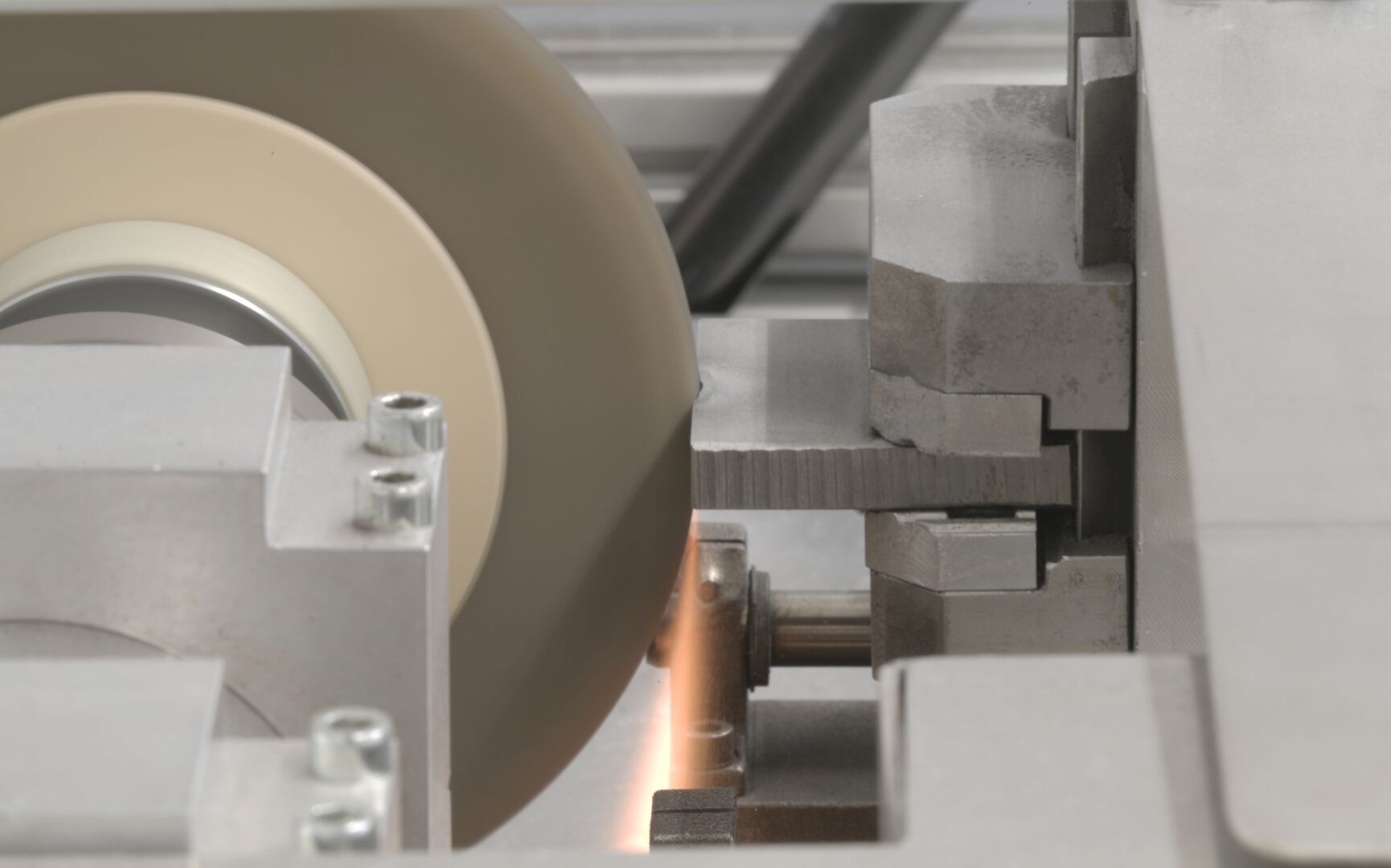

Individual solutions

We brush at the top. Why zeintra? Because we invest our knowledge and experience at our location in Wil in your product and work with you to develop solutions that offer your company real added value.

We brush at the top. Why zeintra? Because we invest our knowledge and experience at our location in Wil in your product and work with you to develop solutions that offer your company real added value.